Improving comfort is deep-seated in our school of thought.

Familiar with the misalignment associated with sitting in chairs, seats, and positions that are not ergonomically correct, we hired an engineer to research problems associated with sitting for prolonged periods of time and went to work developing the best cushion on the market.

Finding and testing high-performance marketable materials.

We began researching alternatives to standard cushions and discovered 3-D spacer fabrics. 3-D spacer fabric material can be engineered to obtain different beneficial cushioning properties and consists of three components: a top layer, a bottom layer, and an interconnecting layer of vertical fibers.

We discovered that different cushioning outcomes could be achieved by varying the fiber properties and orientation of these three layers, so we produced our own proprietary 3-D spacer fabric with properties that could support a seated body comfortably and improve operator stability over commonly used gel cushions.

How it Works

Utilizing this proprietary 3-D spacer fabric, Comfort Cushions are designed to be used over most existing seat cushions* to distribute your weight over a greater surface area and significantly reduce high-pressure points. This in turn improves blood flow to the lower extremities and significantly reduces aches, pains, and swollen legs.

When you sit in a standard truck, airplane, desk, or heavy equipment seat, you sit on top of the seat cushion. But when you add our Comfort Cushion, you sink into a seat molded to your form that supports your weight evenly across a larger area and greatly improves your seated comfort. Technically speaking, Comfort Cushions improve pressure points over original seat cushions by 70% to 100%.

Innovating Comfort Using Pressure Mapping Technology.

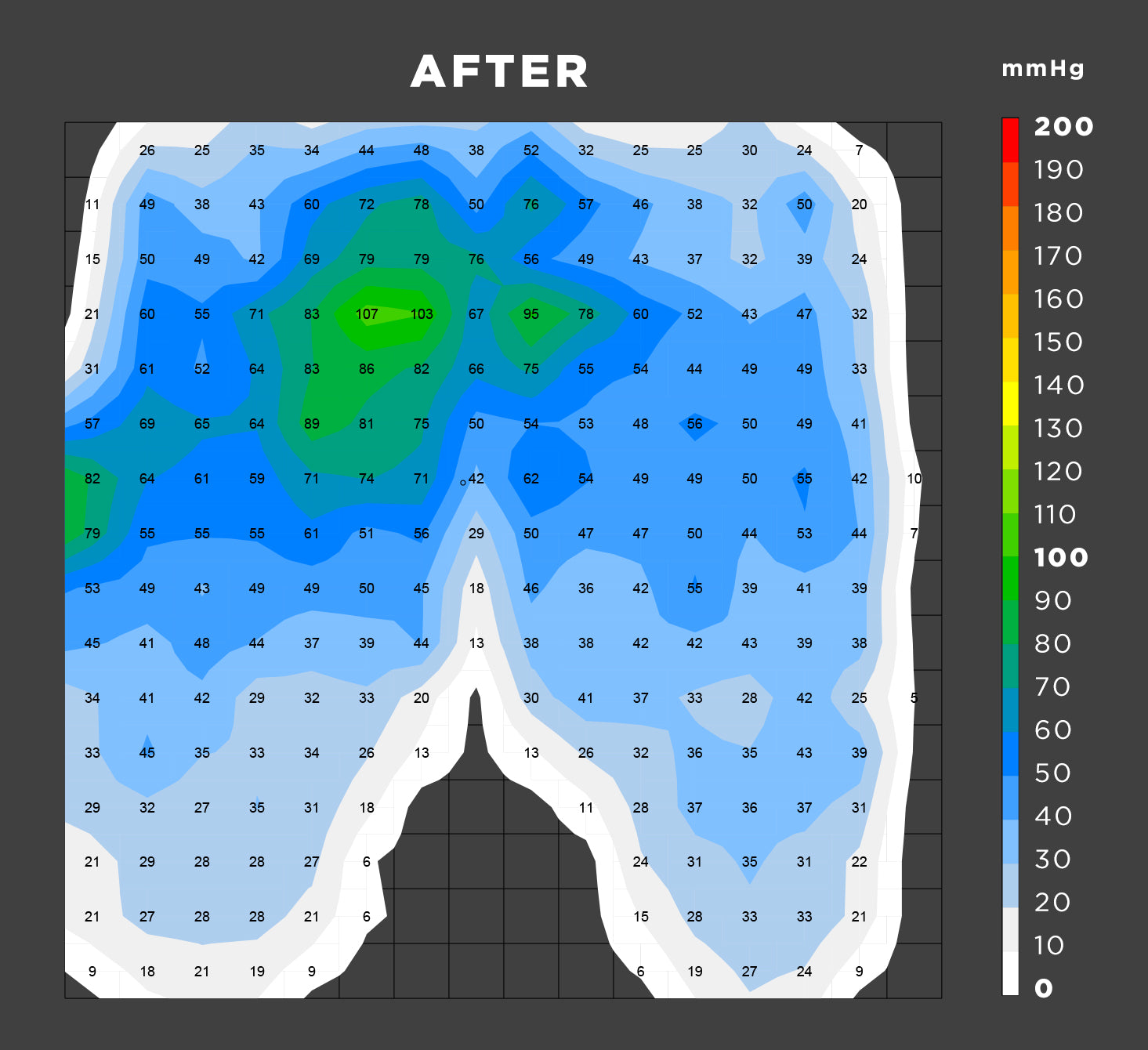

To guarantee performance of our 3-D engineered fabric, we tested our comfort solution using a BodiTrak pressure mapping system.

We tested five popular seats in use in the trucking and heavy equipment industries, along with our prototypes, using 145 lb. and 235 lb. subjects. The BodiTrak pressure sensing mat recorded the distribution patterns and pressures exerted by our subjects when seated on standard cushions, as well as the results when our Comfort Cushion prototypes were added.

“Using our two test subjects, we conducted over 200 individual pressure tests, with 151 devoted solely to adjustments in our 3-D spacer fabric,” explains MacGillivray. “In all tests, the improvements were dramatic.”

Proven Under Pressure.

The following are the results of body pressure mapping conducted on a popular seat widely used in the mining industry and truck seats with our Comfort Cushion added:

Pressure Points Over 100 mm/Hg* = 38

93% REDUCTION

Maximum Pressure = 112 mm/Hg*

22% REDUCTION

*Note: These readings are given in terms of mm/Hg (milligrams of mercury), which is commonly used in blood pressure readings. We determined that any readings less than 100 mm/Hg were beneficial in promoting blood flow to the lower extremities while sitting for extended periods. For more detailed results, please refer to the full pressure mapping report

DISCLAIMER: Our 3-D engineered cushions are designed to improve comfort issues on seats with molded foam cushions only. Use of these cushions on hard surface seats such as benches, plastic and wood surface chairs will not provide any additional comfort benefits. There is no benefit to be expected for any user of this product that is experiencing pain or discomfort as a result of a physical impairment.